Complete guide to swimming pool pump installation, learn it in one go!

The Basic Structure of Pool Pumps

Introduction to Components Such as Impellers and Volutes

Pool pumps are mainly composed of pump impellers, pump volutes\Diffusion guide vane, motors, and pump shafts that connect the center of the impeller and the motor. The following is a detailed .

introduction to each component for you:

Pump Impeller: It is generally composed of two circular cover plates. There are several curved blades between the cover plates. The channels between the blades are the blade channels for water flow. There is a round hole in the center of the front cover plate of the impeller, which is the water inlet of the impeller. The impeller can be said to be the core part of the centrifugal pump. It has a high rotation speed and strong output force. The common closed impeller has high efficiency and low damageability and is widely used in pool pumps. Different types of impellers have different characteristics and applicable scenarios. For example, the flow channel of the channel impeller is a curved flow channel from the inlet to the outlet. It is suitable for transporting liquids containing large particle impurities or long fibers. It has excellent anti-clogging performance, but its anti-cavitation performance is a bit weaker. While the closed impeller has high operating efficiency, can run smoothly for a long time, and the axial thrust of the pump is relatively small. However, it is easy to be wound and is not very suitable for transporting sewage media containing large particles or long fibers.

Pump Volute: Its shape is similar to that of a snail shell and is an important part of the pump. After the impeller rotates and throws out the water, the water will enter the volute. The special shape of the volute can gradually reduce the flow velocity of the liquid, so that a part of the kinetic energy is converted into static pressure energy, allowing the water to flow out along the discharge port at a higher pressure. Meanwhile, the structural design of the volute will also affect the performance of the pump. For example, some volute structures can achieve the self-priming function without setting guide vanes through special designs such as gas-liquid separation ports and return ports on the outer shell, and can also reduce hydraulic losses and noise.

Motor: It is the power source of the entire pump and transmits power to the impeller through the pump shaft to drive the impeller to rotate to achieve functions such as pumping water. High-efficiency motors will not only provide sufficient kinetic energy but also reduce energy consumption and electricity consumption. Motors can be divided into different types such as single-phase motors and three-phase motors. Under the same power, the efficiency of three-phase motors is usually higher than that of single-phase motors. However, when selecting, it is necessary to combine the actual power supply situation and the scale of the pool and other factors to make a decision. For example, for small family pools with a power supply of 220V, single-phase motor pumps can be selected, while for large public swimming pools with a voltage of 380V, three-phase motor pumps can be chosen.

Pump Shaft: It plays a key role in connecting the center of the impeller and the motor and is the main component for transmitting mechanical energy. It transmits the torque generated by the motor to the impeller, enabling the impeller to rotate at a high speed and complete corresponding work such as pumping water.

Understanding these components and their functions can help everyone better understand the basic structure of pool pumps and also lay the foundation for subsequent installation and possible troubleshooting.

Preparations Before Installing Pool Pumps

Preparation of Tools and Materials

In addition, it is also recommended to prepare commonly used tools such as screwdrivers and pipe wrenches to facilitate the operation and adjustment of different components during the installation process. In terms of materials, of course, the corresponding pool pumps and suitable water pipes, plugs, etc. should be prepared. If the purchased pool pump is equipped with a filter element, it is also necessary to check in advance whether the filter element is intact and ensure that it can be installed and used normally. Only by preparing these tools and materials adequately can the installation process be carried out in an orderly manner and avoid installation interruptions or other problems caused by a lack of tools or materials.

Selection of Installation Location

Selecting a suitable installation location has an important impact on the normal operation and service life of pool pumps. First of all, the factors of lift and suction lift should be considered. According to the actual scale and depth of the pool and the overall planning of the water circulation system, determine the position that can make the pool pump perform at its best to ensure that it can smoothly pump out water and carry out cyclic filtration.

At the same time, the ground conditions of the installation location are also very important. A hard and flat floor must be selected for installing the pool pump, which can prevent the pump from vibrating during operation due to uneven or soft ground, affecting its normal operation and even causing damage to components. In addition, the distance between the pump installation position and the water surface should not exceed one meter. Such a distance can ensure that the pump can absorb water smoothly and has sufficient suction.

Furthermore, the overall environment of the machine room should be considered. It is very important that the drainage system of the machine room location is good to avoid situations such as water accumulation soaking the pump and other equipment. The machine room should not be too humid either. A humid environment is easy to cause rust and damage to components such as the motor. And in order to facilitate the subsequent maintenance of the pump and pipes, the machine room needs to reserve enough space to facilitate the maintenance and replacement of parts by staff. In short, comprehensively considering various factors and scientifically and reasonably selecting the installation position is an indispensable part of the installation work of pool pumps.

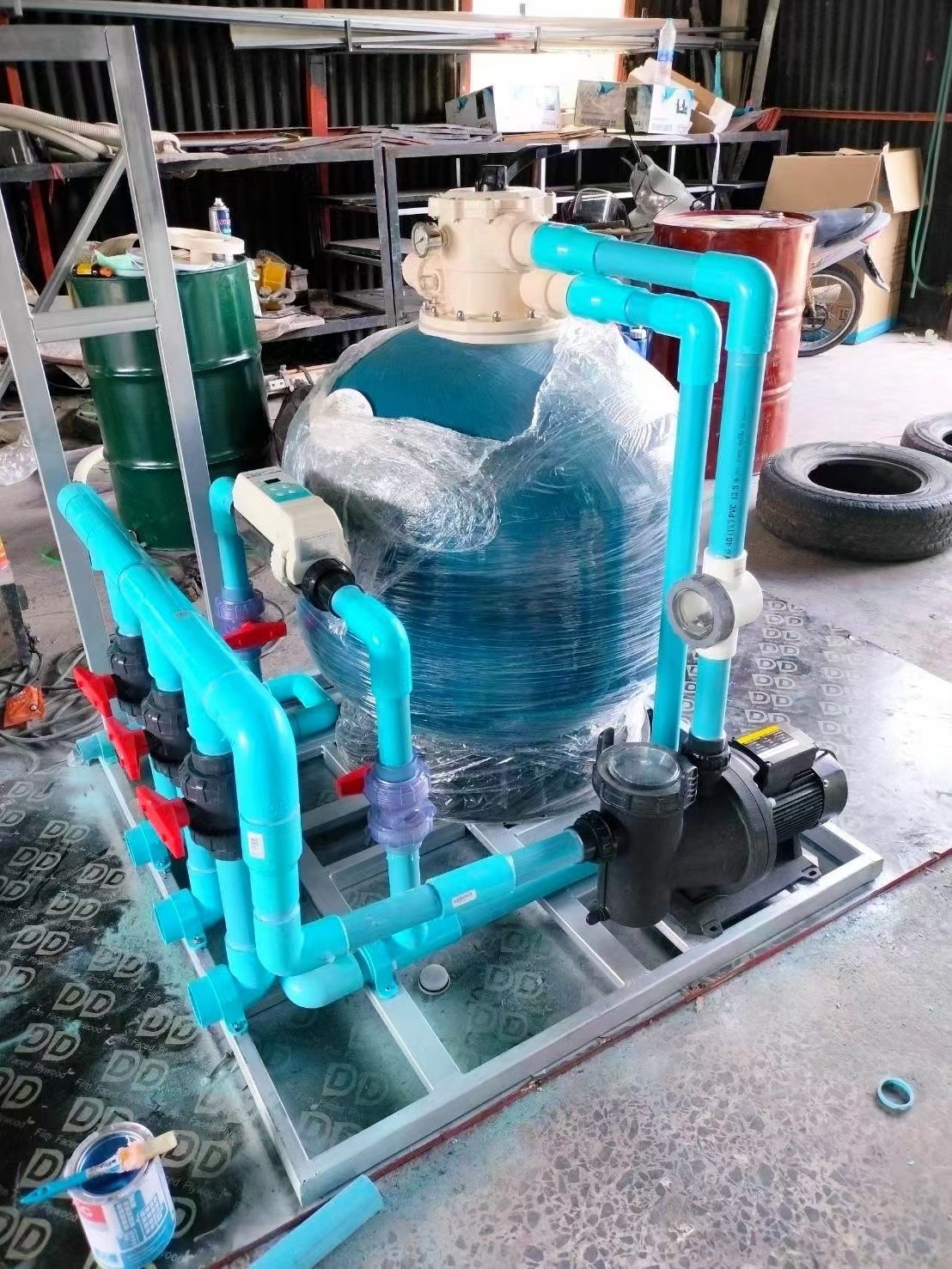

Key Points of Pool Pump Construction and Installation

Requirements for Foundation Construction

First of all, the pump foundation must be constructed according to the design drawings. The anchor bolts for stabilizing the motor should be firmly integrated with the concrete foundation. Before pouring concrete, the embedded holes must be cleaned thoroughly to avoid residue of debris affecting the bonding effect. Meanwhile, the bolts themselves should not be skewed, and their mechanical strength should meet the requirements. Only in this way can a reliable foundation be provided for the stable operation of the pool pump and prevent problems such as excessive vibration and component loosening due to an unstable foundation in the future.

Requirements for Vibration Reduction and Connection

The pump base should be placed on shock-absorbing rubber pads, and the rubber pads should be in close contact with the foundation surface. The separation bolts equipped on the outer shell should be treated by hot-dip electroplating to enhance their durability and corrosion resistance. In terms of the connection between the pump and the motor drive shaft, the allowable axial and radial errors should not exceed the specified values. Only by strictly controlling the error range can it be ensured that the pump and the motor work well together during operation, so that the entire pool pump can run stably after installation and meet the corresponding specification standards and reduce unnecessary failures and losses.

Key Points of Pipe Connection

When connecting pipes, the reducing pipe or expansion pipe should be directly connected to the pump first, and the installation of the pump piping should be carried out after the pump is positioned, leveled and stabilized. It should be particularly noted that the pump equipment should not bear the weight of the pipes. The installation sequence is flexible shock-absorbing joints, valves, and then firmly fixed to the pump. In addition, the flange of the piping should match the flanges of the pump and valves to ensure that the connections between various components are tight and suitable. When installing valves, the direction of the handle should be convenient for operation, the elevation should be consistent, and the piping should be arranged neatly. Only in this way can the correct pipe connection be ensured, the water flow be transported smoothly, and the entire pool water circulation system can operate normally.

Electrical Connection Specifications

In terms of electrical connection, comprehensive protective measures should be taken to prevent accidental contact and ensure the safety of use. The junction box should be suitable for flexible connection, which can better meet the connection needs under different working conditions and can also avoid electrical failures caused by improper connection to a certain extent, ensuring that the electrical installation is both safe and meets the specification requirements, so that the pool pump can be powered on stably and reliably.

Testing and Inspection After Pool Pump Installation

Power-on Testing

After the installation of the pool pump is completed, the next step is to conduct power-on testing. First of all, a water flow test must be carried out, and then the plug of the pump should be carefully inserted into the matching power socket, and then the power should be turned on. At the moment of power-on, carefully observe whether the pump can operate normally. Under normal circumstances, the pump will start and run relatively smoothly without stuttering.

At the same time, pay attention to whether there are abnormal sounds during the operation of the pump, such as harsh friction sounds, clicking sounds or other irregular noises. These abnormal sounds are likely to mean that there are improper installations of the internal components of the pump. For example, there may be contact friction between the impeller and the volute, or problems may occur in parts such as the bearings of the motor.

In addition, also feel whether the pump as a whole has abnormal vibrations. Excessive vibration may not only affect the service life of the pump itself but also indicate that there may be flaws in the installation process, such as an unstable foundation or poor vibration reduction measures. If any of the above abnormal situations are found during the test, the power must be turned off immediately, and then the problem should be carefully checked to avoid further damage to the pump and ensure that the pump can be safely and normally put into use in the future.

Component Inspection

After the power-on test is completed, it is also necessary to conduct a detailed inspection of the installed pump components. You can gently turn the pump shaft by hand. During the turning process, carefully listen to whether there is a friction sound or a stuck phenomenon in the impeller part. If you can clearly hear a friction sound, it may be that the position of the impeller installation is deviated and it has touched the surrounding components. If the impeller is stuck and does not move, it is necessary to consider whether there are foreign objects entering the space where the impeller is located or whether there are errors in the assembly process of the impeller itself. For example, reasons such as the connection between the impeller and the pump shaft is not fixed properly may lead to such problems.

In addition to the pump shaft and impeller, also check other connection parts of the pump, such as the connection between the pipeline and the water inlet and outlet of the pump, to confirm whether the seal is good, whether there are signs of looseness or leakage; and also check the wiring part of the motor to see whether the circuit connection is stable and whether there are safety hazards such as exposed wires. Through a comprehensive inspection of each component, ensure that the overall installation is accurate and error-free, so that the pool pump can operate normally and play its due role, providing a reliable guarantee for the water circulation of the pool.

Tips for Daily Maintenance of Pool Pumps

Cleaning and Replacement of Filter Elements

The filter element of the pool pump plays a key role in the entire filtration system. Regular cleaning and timely replacement of it can effectively ensure the filtration effect and keep the pool water clean and hygienic.

First, let's talk about the cleaning of the filter element. The filter element needs to be cleaned regularly. This is because during the pool water circulation process, impurities, hair, microorganisms, etc. in the water will be continuously intercepted by the filter element. If it is not cleaned for a long time, the filter element is easy to be clogged, resulting in poor water flow and further affecting the pumping efficiency of the pump and the normal operation of the entire water circulation system. Generally speaking, when it is found that the water output of the pump is significantly reduced or the reading of the pressure gauge changes abnormally, the filter element should be cleaned. The cleaning method is relatively simple. First, turn off the power of the pump to ensure operation safety, and then carefully take out the filter element according to its installation method. If the filter element is not particularly dirty, it can be directly rinsed with clean water to wash off the impurities attached to the surface. If the filter element is relatively dirty, such as having a lot of oil stains, algae, etc., you can prepare an appropriate amount of mild detergent, soak the filter element in warm water with detergent for a period of time, and then rinse it repeatedly with clean water until the flowing water becomes clear. After rinsing, dry it in the air or wipe it dry with a clean towel, and then put it back in place.

Regarding the replacement cycle of the filter element, it should be determined according to the usage frequency of the pool, water quality conditions, and the material and specification of the filter element itself. Generally speaking, it is recommended to check the state of the filter element once every quarter or every half a year. If it is found that the filter element is damaged or deformed, or the filtration effect is still not ideal after multiple cleanings, it is necessary to replace it with a new filter element in time. Generally, for small family pools with moderate usage frequency, replacing the filter element once a year can basically meet the filtration requirements. However, for public pools or pools with frequent usage and complex water quality, it may be necessary to replace the filter element every quarter or even in a shorter period of time. In short, following the manufacturer's instructions and combining the actual usage situation, regularly cleaning and replacing the filter element is a very important part of the daily maintenance of pool pumps.

Maintenance Key Points of Motors

The motor is the power core of the pool pump. Regular maintenance of it can extend the service life of the motor and ensure the stable operation of the pool pump.

In daily life, attention should be paid to cleaning the motor and its related components. During the operation of the motor, dust is easily adsorbed on the surface. If too much dust accumulates over time, it will affect the heat dissipation performance of the motor and may further lead to overheating and failure of the motor. So you can regularly use a clean and soft rag to gently wipe the outer shell of the motor to remove dust. For the motor fan, it also needs to be cleaned. If the fan is entangled by debris or a large amount of dust is attached to the fan blades, its rotation efficiency will be reduced, affecting the heat dissipation and ventilation effect of the motor. When cleaning, also use soft tools to carefully remove the foreign objects and dust on the fan to ensure that the fan can rotate smoothly.

In addition, checking the motor bearings is also a key matter in motor maintenance. After the motor bearings have been running for a long time, the lubricating oil inside may gradually decrease or deteriorate. At this time, it is necessary to check whether it is necessary to add oil or replace the bearings. You can initially judge by listening to the sound when the motor is running. If you hear abnormal friction sounds or noises, it may be that the bearings have problems. Then further check the wear situation of the bearings. If the wear is relatively serious, a new bearing should be replaced in time. If it is just a lack of lubricating oil, you can add lubricating oil according to the regulations.